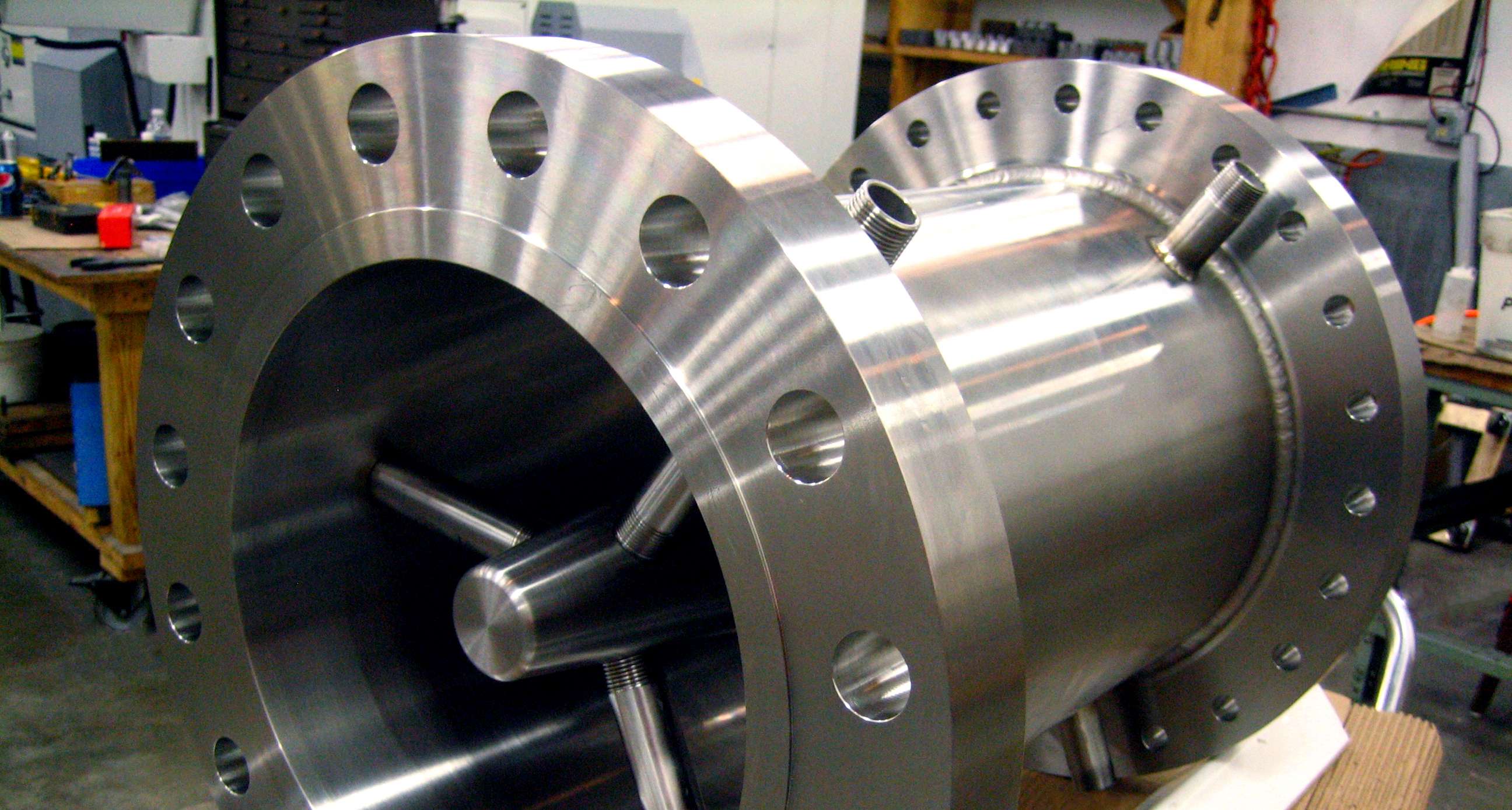

BTI manufacturers large, complex, precise tools, assemblies and components for aerospace, defense and energy sectors. BTI is an AS9100/ISO9001 certified company that has approved supplier status with Pratt & Whitney, Sikorsky, Lockheed Martin, Mitsubishi, GE and many others.

ABOUT BTI

BTI Manufacturing = Capacity. Experience. Quality.

- BTI has competently served manufacturing requirements for many Fortune 500 companies, including the following notable clients and projects:

- Motorola – Personal Communications Assembly Fixtures and Conceptual Prototype Parts.

- Pratt and Whitney – Aircraft Non Complex Ground Support Equipment, such as Supports, Lift Adapters, DLT Adapters, Pushers/ Pullers, and Engine Assembly Tooling.

- BTI continues to forge ahead to produce high quality products on time, meeting the demanding needs of its customers.

- BTI has an in-house engineering team with over 15 Years experience, equipped with the latest CAD/CAM software running on powerful workstations. The BTI engineering team would be pleased to quote your next critical tooling requirement.

For more information, fill out our online quote request form, or please contact: Swamy Setty, President | Phone: (561) 844-3711

BTI Provides Customers with Precision Machining, Advanced Fabrication Solutions and Engineering Support that Includes:

- CNC horizontal boring mill: capable of machining 120” long x 80” wide x 70” tall.

- CNC vertical milling up to 60” length x 20” wide.

- CNC vertical turning: capable of turning up to 157” diameter and 65” tall.

- Manual horizontal turning: capable of turning up to 144” in length and 17” in diameter.

- CNC water jet process: cuts up to 7” aluminum & 5” steel. Table size 96” x 144”

- 5 axis CNC wire EDM machines that can handle parts up to 16” high.

- Inspection: portable 9ft arm (FARO) capable of inspecting large complex parts, CAD-to-part analysis, and reverse engineering.

- Materials including steel, stainless steel, aluminum, titanium, high temperature alloys, and non-metallic materials such as plastics & delrin are fabricated.

- E2 software: shop floor management system

- BTI currently uses CAM software compatible with IGES, AutoCAD, DXF and several file systems.

- Production Area: 19,000 square feet of manufacturing space.

- BTI machinists have an average of 15 years experience in machining complex & intricate parts.

- BTI welders have AWS qualification required for welding complex shapes and various metals. Qualified to weld steel, stainless steel, aluminum, and titanium.

BTI Clients

United Technologies (Pratt & Whitney Aircraft, UTRC) | Lockheed Martin | Sikorsky Aircraft | Power Systems (Division of Alstom, Division of GE)

and various customers in the automotive, semiconductor and marine industries

Location: Riviera Beach, Florida

Production Area: 19,000 square feet of manufacturing space

P&W Supplier Code: 73197

Sikorsky Supplier Code: 008719

Lockheed Martin Supplier Code: LM0224540

DUNS Number: 113384932

Cage Code: 1ZBG5

Minority & Woman Owned Business

DUNS Number: 113384932

Cage Code: 1ZBG5

Minority & Woman Owned Business

THE BTI TEAM

Swamy has over 25 years of manufacturing experience, having held management positions at Xerox, Digital and EDS. Extensive international experience in Asia, Europe and Latin America. Responsible for strategic growth of the company by providing world class services in terms of cost, quality and delivery. Swamy has BS in Mechanical Engineering and MS in Metallurgy and Materials Sciences from Case Western Reserve University.

Kiran brings over 10 years of financial and operational experience to BTI. Prior to joining, he was a senior hedge fund accountant at HSBC. Kiran is responsible for the strategic and financial initiatives at BTI. Implemented E2 software management system to streamline procurement, material flow, and inventory operations. He determines present needs of customers to invest in equipment and processes accordingly. Kiran graduated from New York University with a Major in Economics. He also received a Certificate of Advanced Accounting Proficiency from Santa Clara University.

Robert (Bob) is an experienced veteran in the tooling and manufacturing industry. He has more than 25 years of experience in aerospace and defense industries. He brings his expertise when fabricating large and complex tools. As general manager, Bob is responsible for the execution of all the customer orders, managing the work flow through the shop, and prioritizing jobs to meet delivery dates.

William has more than 15 years of experience in inspection and quality. He is well versed in quality management systems and spear headed the task of qualifying the company to achieve the AS9100 and ISO 9001 certification. William is responsible for all the quality of the products and bringing in new processes to reduce the inspection time and improve our quality management system.

The average experience of an employee is 15+ years with specialized knowledge in tool building, part and assembly manufacturing. The staff is well versed in CNC programming and tool design. Employees have backgrounds in aerospace, defense, and medical manufacturing industries.

BTI’s Equipment

- Two 5 axis CNC horizontal boring mill, Femco BMC 110R2 with Fanuc 2li-MB controller (travel is 78” x 70” x 66”) CAT50

- 2 axis CNC open side vertical turning lathe, O-M TMS 2-20/40 with Fanuc 2li-MB controller with a 96″ diameter table with the capability of turning a 157.5″ diameter x 65″ tall

- 3 axis CNC vertical milling machine, Mazak, Model #MTV 515/40N with Mazatrol P/N: 640-PC-fuison-CNC (table size 21″ x 51″) CAT50

- 5 axis CNC water jet, PAR SYSTEMS VECTOR Ingersoll-Rand (table size is 96″ x 144”)

- 4 axis CNC Lathe/Mill (live tooling) 15″ diameter x 25″ GANESH KSL-7216 TMY with conveyor and a Mitsubishi M70L controller

- Manual engine lathe GANESH GT-26160 with a 33″ diameter with a gap out (table size is 26″ DIA x 160″)

- FARO’s Edge, 9ft, 7 axis portable measurement arm

- 7 axis CNC Amada press brake: 143 tonnage, 10’ bed length

- Coordinate measuring machine (CMM), MITUTOYO model #BRT-M 707

- Mitutoyo Optical comparator model #PH-A14 series

- Two 5 axis CNC wire cut EDM, CHARMILLES Robofill 440SL (table size 14″ x 22″ x 16″ under “Z”)

Amada HDS1303NT

Femco BMC-110R2

Mazak #MTV 515_40N

O-M TMS

FARO

Products Produced by BTI

Tools and fixtures for civilian and military turbine engine platforms:

Aerospace Tooling

& Assemblies

Rocket Engine Program

Assembly

Flight Test Part

Helicopter Maintenance Tool

Underwater Parts & Assemblies

Certifications

ISO 9001:2015 and AS9100D: Complete Aerospace Quality Management System: specializing in the manufacturing of precision machined parts, tools, and assemblies for commercial, government, and the aerospace industries.

Perry Johnson Registrars, Inc.

ANAB- The aerospace AS standards contain the requirements of ISO 9001 and additional industry requirements. Some major aerospace manufacturers recommend their suppliers be AS certified. This certification must be issued by CBs accredited to the AS standards by a body recognized by the International Aerospace Quality Group (IAQG) or the Americas Aerospace Quality Group (AAQG). ANAB is recognized to accredit CBs to AS9100, AS9110, and AS9120.

BTI: Careers & Contact

(561) 844-3711

4128 Westroads Dr. Suite 225 | West Palm Beach, FL 33407

Careers at BTI

BTI is growing and we are always looking for talented individuals with experience manufacturing complex, large, and precise tools, assemblies and components for aerospace, defense, and energy sectors industries.To apply simply e-mail your resume to: [email protected]